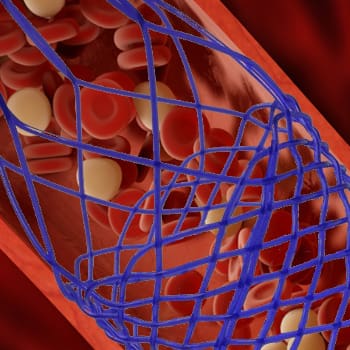

Medical Device Development Services

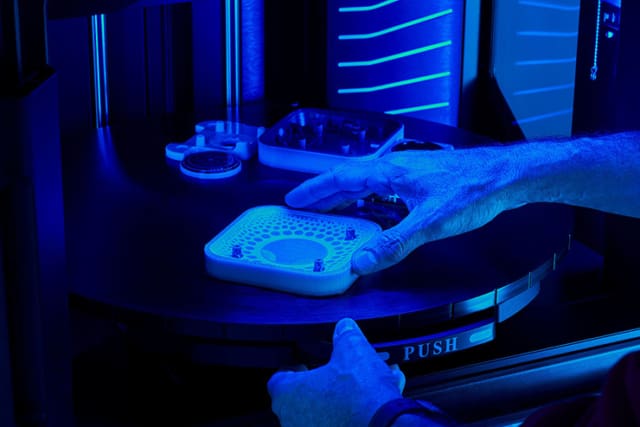

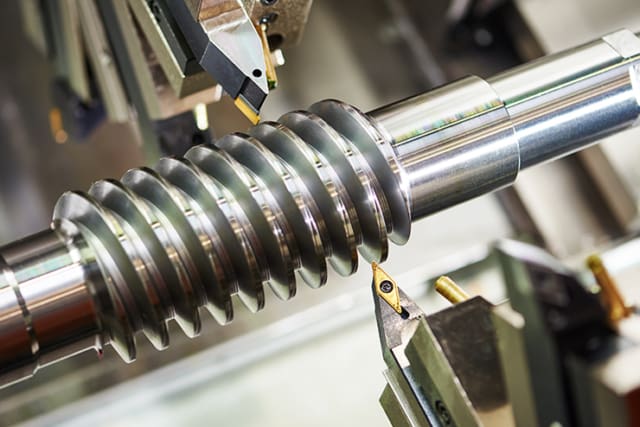

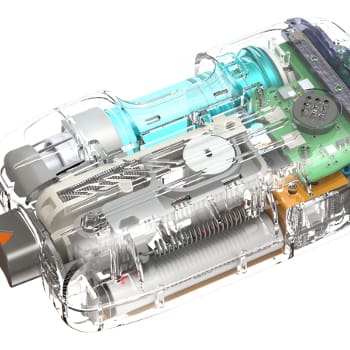

- Comprehensive hardware, software, & automated systems development

- Transforming new technologies into new devices for over 20 years

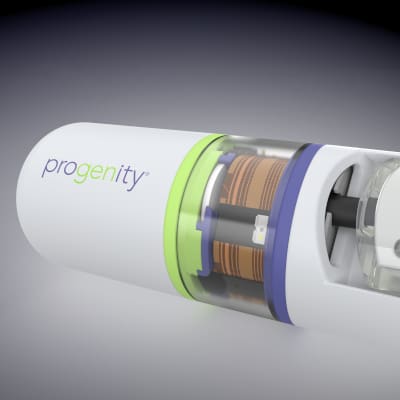

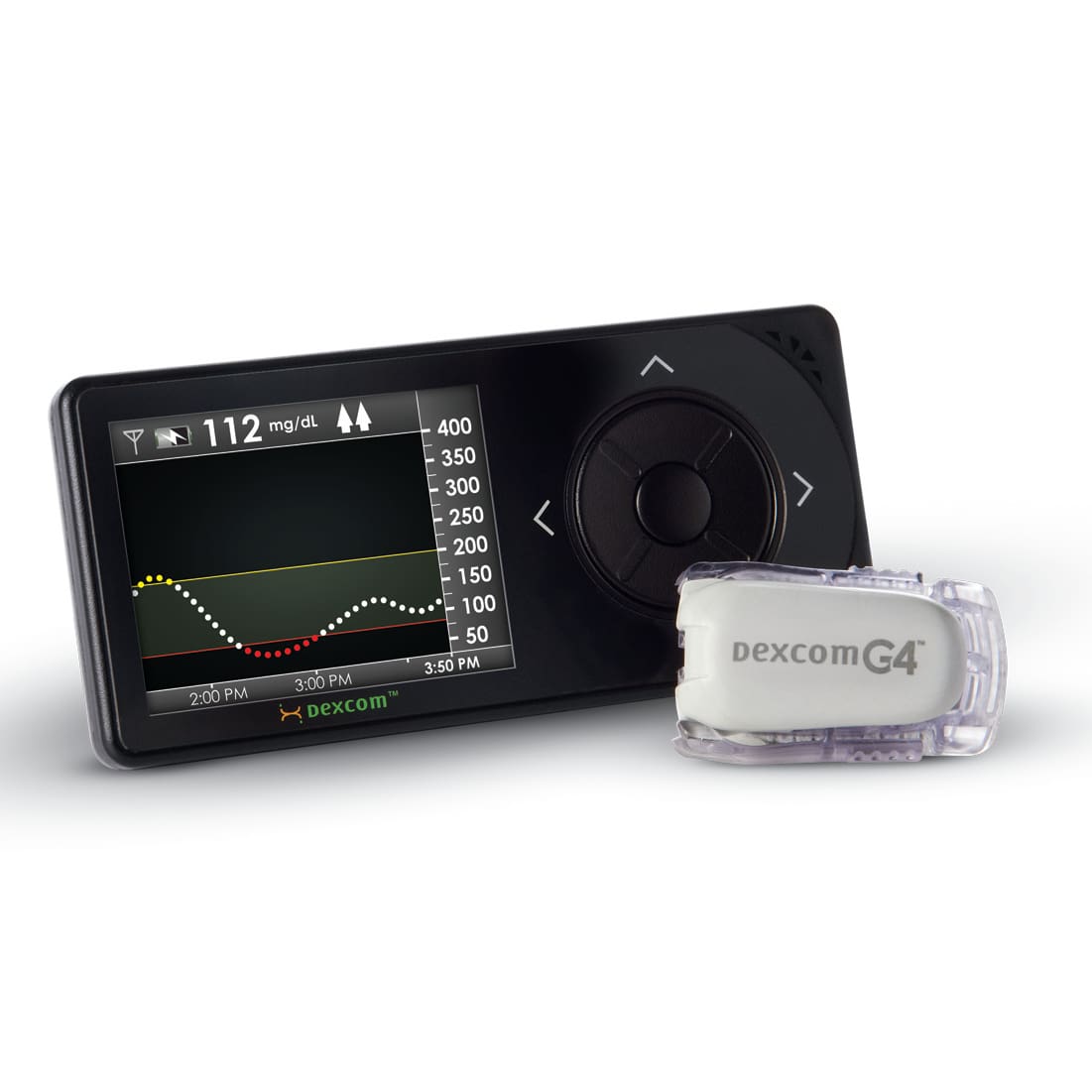

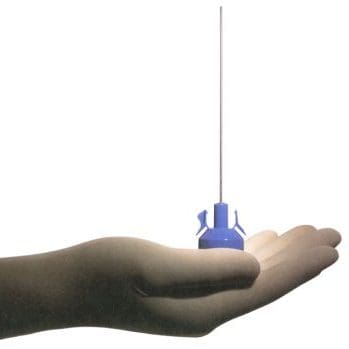

- Broad range of Class I, II, & III device development

- Single-use, consumables, durables, & companion apps

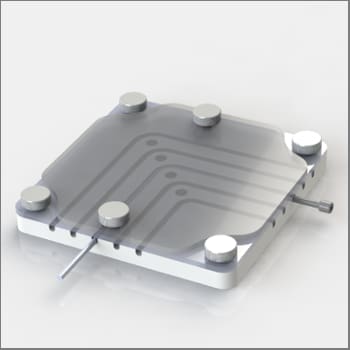

- Onsite machining, rapid proto, BSL-2 lab, assembly, & DVT labs

- Seamless integration of hardware, firmware, and application software for system-level performance

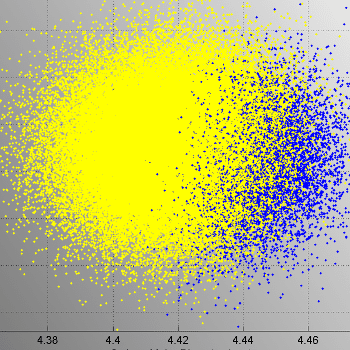

- Early technical risk identification and mitigation to reduce delays and total development cost

- Design control documentation developed in parallel with engineering for smoother regulatory submissions

- Proven process that supports clinical trials, manufacturing transfer, and long-term product success

Customer Voices

Medical Device Case Studies

Transform your core technology into a groundbreaking new device.

Begin your journey with NOVO today!