INDUSTRY EXPERTS FOR COMMERCIAL INKJET AND 3D PRINTER DEVELOPMENT

NOVO’s expertise in piezo and thermal inkjet technology, writing systems development, and jettable materials development gives our inkjet and 3D printer clients the same printer development services and expertise found at major printer companies.

Inkjet Small Format

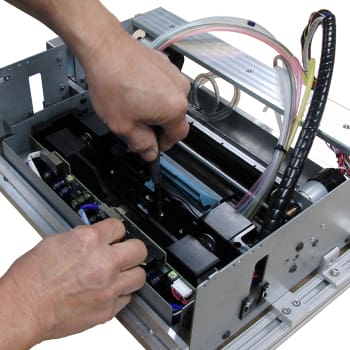

Inkjet Small-format consumer and office printers are high-volume, high-performance, and low-cost systems. These products require a broad engineering skillset that includes mechanism and enclosure design, precision motion control, materials, high-volume consumables development, design for manufacturability, reliability, and usability – not to mention current knowledge of printheads, inks, additives, media, and printing algorithms to achieve the desired image quality.

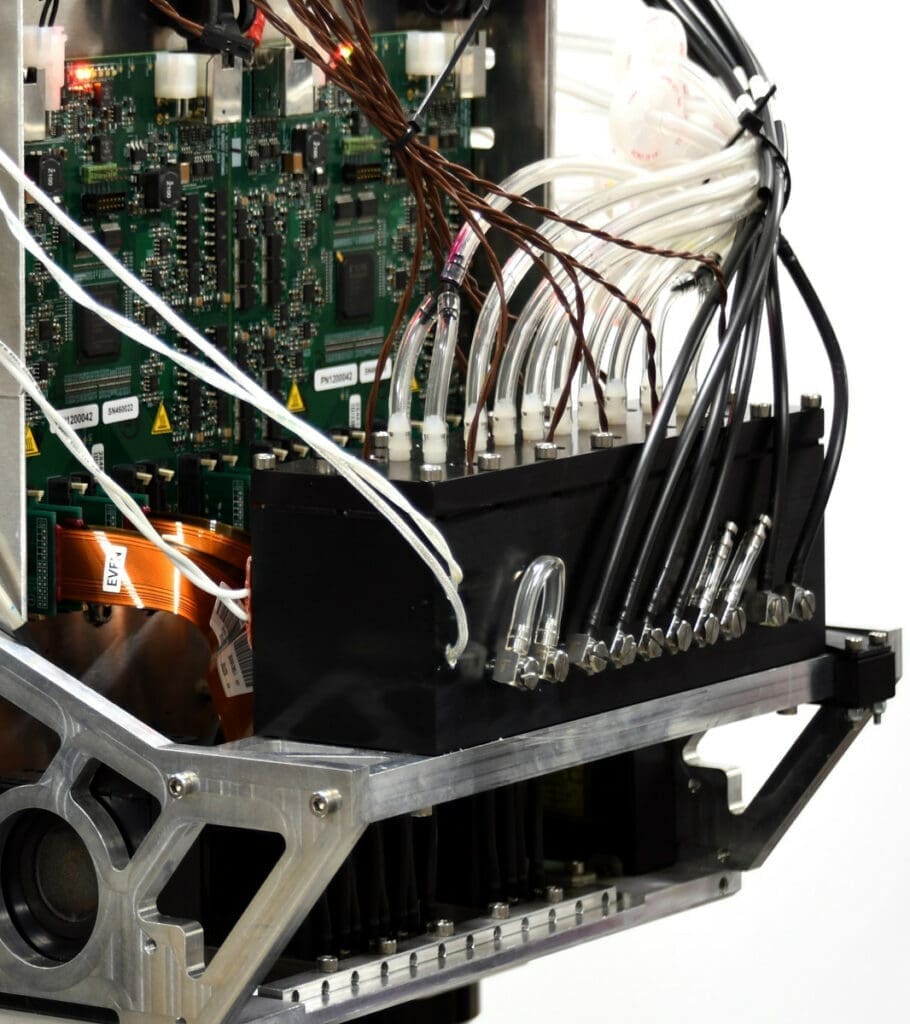

Inkjet Large Format

Inkjet Large-format UV and specialty printing systems for industrial, high-speed digital printing or fine art applications require the same or greater precision as small-format applications, and design and manufacturing approaches suited to the lower volumes and more demanding use environments of these product types.

3D Printers

3D Printers using piezoelectric and thermal inkjet printing technologies have evolved beyond form-and-fit prototyping to functional prototyping and low-volume manufacturing applications. Advances in 3D printing and materials technology have extended the use of 3D printing systems further into the product development lifecycle. Dimensional accuracy, material properties, feature definition, and throughput have all steadily advanced. Engineers have become expert in optimizing their use of 3D printing during the development of new products. Often, engineers mix 3D printed components with more traditional fabrication methods according according to the demands on individual components. Design cycles are accelerated and greater levels of refinement achieved at earlier stages of development.

Configure to Order Printer Systems

Configure to Order custom application printers leverage our library of already-developed software and hardware building blocks to create inkjet and 3D printer platforms for special applications such as direct-to-object printing on curved surfaces, conveyorized printing, food-safe printing, and more. These industrial platforms are used by clients in their manufacturing process to customize existing products. Development of these systems is accelerated by leveraging our existing modular solutions.

NOVO knows the major printer companies, contract manufacturers, and supply chains for printers, printheads, cartridges, key components, and subsystems, as well as the printer processes used by the major printer companies. Our engineers have developed new platforms and proprietary technology for many of these companies. We can do the same for you.

Selected Areas Of Printer And Dispensing Expertise

- New 3D printer platforms

- Consumer appliance

- All-in-one business

- Wide format, UV-cured piezo printing

- Retail photo lab

- Industrial

Ink And Media Development Capabilities

- Comprehensive dye- and pigment-based ink development

- Microfluidics

- Media coatings

- Media construction

Auxiliary Systems

- Laminators

- Single- and multi-axis cutters

- Stackers

- Sorters

- Bookbinding

- Roll, sheet feed, and roll-to-roll systems

- Duplexers

Writing System Development Capabilities

- Swath advance accuracy

- Wrap angle and tangential media drives

- Analog encoders

- Automated swath advance measurement

- Transition error analysis (bottom/top form transition)

- Bidirectional print alignment

- Pen alignment

- Multi-color inks

- Drop flight-time compensation

- Print zone media control (pen-to-paper spacing)

- Pen servicing

- Wiping algorithms

- Spit algorithms

- Service station mechanics

- Borderless printing

- Dot-to-dot placement (tolerance study)

- Media edge detection

- Print-on-acceleration ramp

- Print modes

- Bidirectional and unidirectional print algorithms

- Multi-pass printing, print masks

- Draft modes

- Drop depletion

- Aerosol control

- Ink chemistry development and tuning

- User print quality metrics and evaluation

- High-speed and high-accuracy dispensing

- Dispensing of low- to medium-viscosity fluids