A METHOD TO EVALUATE STENT CONFORMABILITY IN VITRO

THE CLIENT’S REQUEST

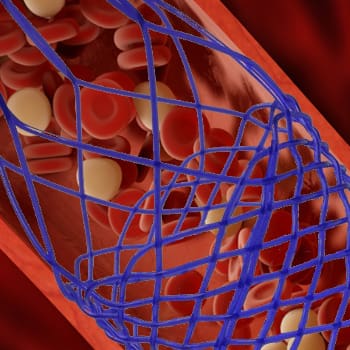

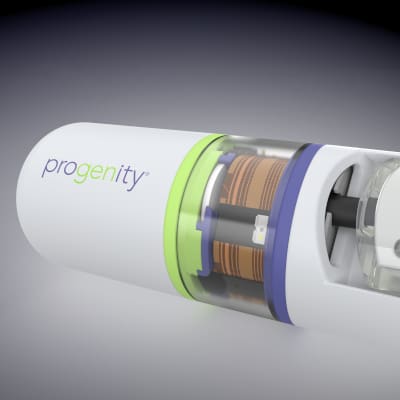

A medical device company had a revolutionary coronary artery stent that was being tested for conformability to the inside of the artery. Stent conformability had previously been tested by the client using low-power magnification visual light inspection; however, this method did not allow imaging of the inside of the stent. Stent features or poorly apposed stent segments that protrude into the path of blood flow after deployment pose a risk to patient safety (stent thrombosis, potentially leading to acute myocardial infarction), and therefore, a benchtop inspection method for occurrences of this type needed to be established for design verification.

A NOVO engineer developed a test method and made novel use of an existing inspection instrument that allows not only inspection of the inside of this stent, but facilitates more objective quantification of the test data and development of quality specifications. This effort also allows more reliable comparisons in performance between new and previous generations of the implant.

STENT CONFORMABILITY TEST METHOD

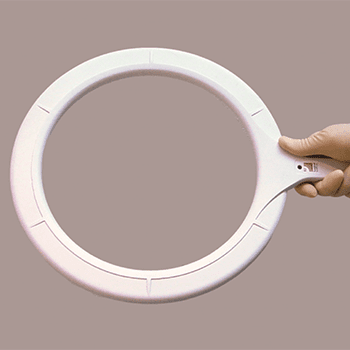

NOVO’s experienced medical device engineer developed two test plates: one with straight channels and one with channels having 90° bends of decreasing radii into which an artificial artery can be placed. The channels are designed to accommodate the wall thickness of the artificial artery, the stent thickness, and the compliance of the stent delivery system balloon.

Stent system samples are delivered into each artificial artery and expanded to nominal diameter, deploying the stent and conforming it to the wall of the artery. Upon release of pressure, the stent retains a level of conformance to the artery relative to the bend and radius of the channel. Inability of stent features to retain conformance is available for inspection and comparison to established product specifications.

This test method and associated fixtures are configured for both nominal inflation pressure and the rated burst pressure.

RESOLUTION

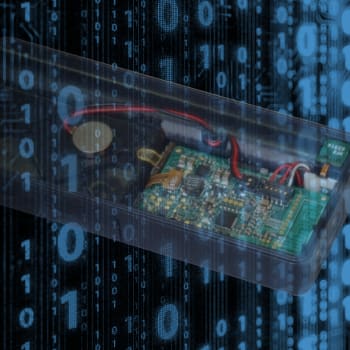

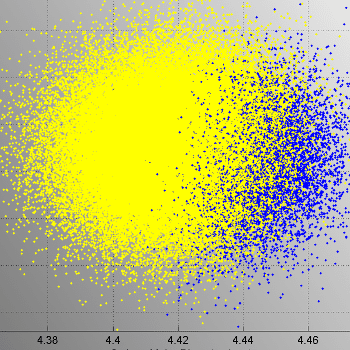

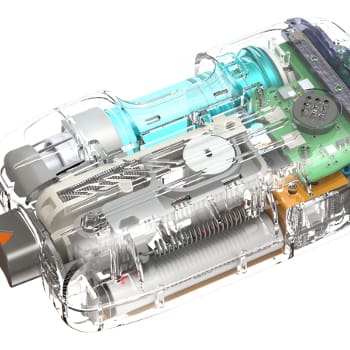

The engineer learned that a computed tomography (CT) scanner was already in use in the operations department of the client facility, which provided a novel option for virtual 3D inspection of the stents using this equipment. This cost-effective method allows inspection of the inside and outside of the stent while expanded within the artificial arteries. The engineer established this CT inspection method with the client through proof of concept. The effort has provided a means for the client’s quality engineering group to characterize the feature defects and determine initial clinically relevant acceptance criteria.

Read about testing for stent deliverability conforming to ISO 25539-2:2012 here.