Data-driven intraoperative software improves precision and efficiency in spinal rod bending

Client Need & Project Overview

Long before terms like “AI-powered surgical assistance” or “augmented spine surgery” gained traction, NuVasive—a leader in minimally invasive spine surgery—was pushing the limits of intraoperative decision support. To enhance surgical predictability and reduce time spent on manual adjustments, they envisioned a system that could transform real-time spatial data into precise rod-bending instructions during spinal fusion procedures.

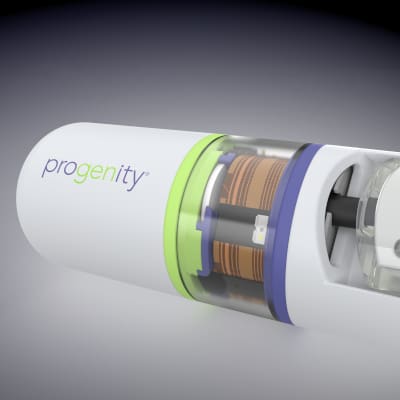

NuVasive partnered with NOVO to develop a software application that integrated with their proprietary hardware and the Integrated Global Alignment™ (iGA) platform. The solution needed to ingest 3D intraoperative data, calculate optimal rod curves, and output bend instructions that aligned with both the patient’s anatomy and the physical constraints of the surgical tools.

Key Engineering Challenges & Solutions

| Challenge | NOVO’s Solution |

|---|---|

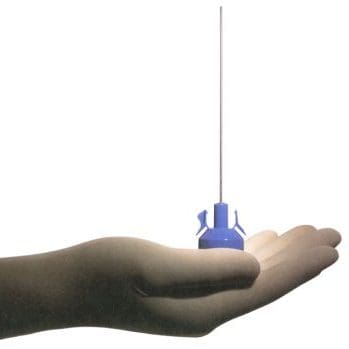

| Capture precise 3D geometry of implanted pedicle screws | Developed a real-time interface with an infrared optical tracking system and stylus, capturing the spatial location and orientation of each screw with sub-millimeter accuracy |

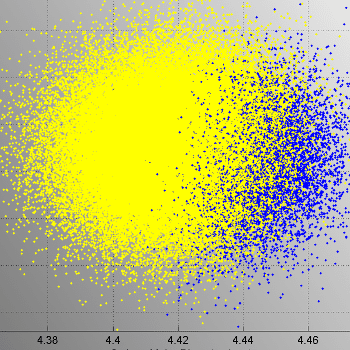

| Convert screw data into an ideal rod profile | Employed a blend of vector calculus, numerical analysis, and early-stage machine learning techniques to calculate custom rod contours |

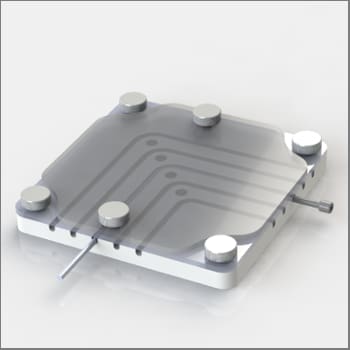

| Maintain bend feasibility within physical constraints | Incorporated checks for material limits, rod diameter, smoothness of curvature, and user-specified tolerances such as rod overhang |

| Compatibility with aseptic manufacturing | Designed the fluid path to support automated aseptic fill and finish lines while maintaining a closed system. |

| Provide intuitive, real-time feedback during surgery | Designed a custom interactive UI using C#.NET WPF with both coronal and sagittal visualizations, showing the evolving construct and proposed rod shape |

Vision to Verified System

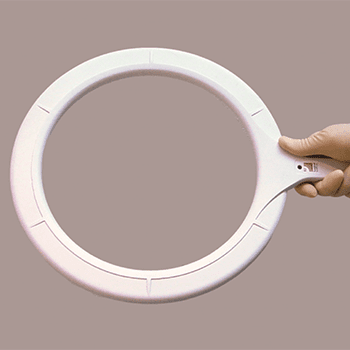

A solution designed to simplify a manual surgical step became an early example of intelligent, intraoperative workflow design. The final software application powered the Bendini spinal rod-bending system, delivering computer-assisted bend instructions that could be executed with confidence in the OR.

The solution anticipated several trends now defining modern surgical platforms:

- Real-time intraoperative data integration: capturing and acting on spatial information during surgery

- Digital visualization: mirroring surgical constructs with virtual models for planning and verification

- Procedure-specific AI and automation: automating complex biomechanical calculations while respecting material and device limitations

NOVO’s interdisciplinary team brought together expertise in computational mathematics, machine learning, user workflow design, and hardware-software integration. The result was a surgical planning tool that felt like the future—even then.

Results & Impact

Bendini became a widely adopted innovation and key component of NuVasive’s iGA platform. By enabling surgeons to work more efficiently and precisely, it helped reduce OR time and improved the consistency of spinal alignment outcomes—paving the way for today’s data-driven, software-augmented operating rooms.

Animation and photography supplied courtesy of NuVasive, Inc.

Software Display of Spinal Rod Bending Program

Why NOVO Engineering?

Developing surgical software requires more than just writing algorithms or building interfaces. At NOVO, we specialize in working through the technical complexity that comes with regulated hardware-software systems.

We’re comfortable operating in the gray areas—when requirements are still evolving, integration is nontrivial, and the stakes are high. Our teams bring together expertise in applied mathematics, real-time systems, and device interoperability, along with the discipline to document and validate everything for regulatory submission.

For this project, that meant:

- Translating 3D spatial data into actionable instructions that surgeons could trust

- Building a user interface that made sense in a high-pressure OR environment

- Accounting for physical limitations of hardware and materials during calculation

- Supporting an iterative development process with a large device manufacturer

We don’t try to be everything. We focus on solving hard technical problems in medical and life sciences systems—especially where software and hardware meet.

Let’s build what’s next

If you’re developing a system where software, hardware, and clinical workflow need to tie together seamlessly, we’d be glad to learn more.

Whether you’re defining requirements, building a prototype, or preparing for commercialization, we can help assess feasibility, identify technical constraints, and accelerate development.

Contact us to schedule a discovery call about your next development project.