Design for Manufacturability of an Early IoT-Enabled Medication Adherence Device

Client Need & Project Overview

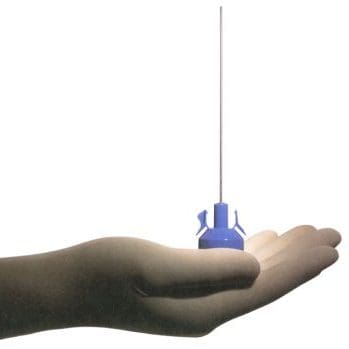

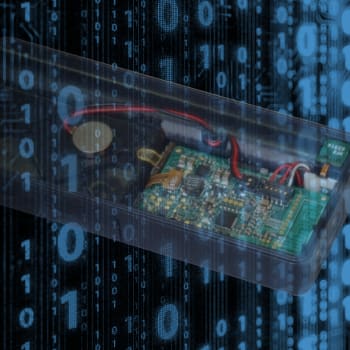

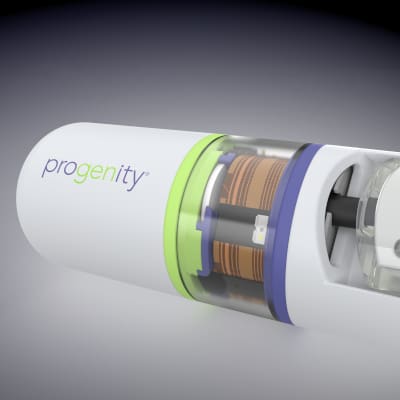

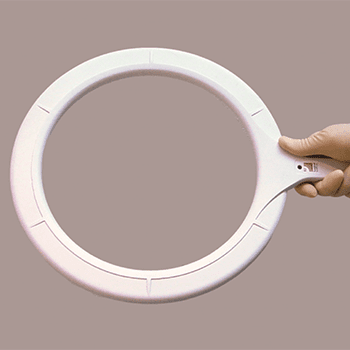

Long before today’s surge in connected health platforms, one startup was ahead of the curve. Their vision: a smart, cloud-connected prescription bottle cap designed to improve medication adherence. The device offered visual and audio reminders, enabled automated refill ordering, and transmitted usage data to caregivers and physicians. These are now core features in many modern digital health tools.

To prepare the product for full-scale production, the client needed design for manufacturability (DFM) expertise. After a successful pilot run, they planned to ramp up to 20,000 to 30,000 units per month. NOVO was selected for its deep experience with high-volume electromechanical assemblies and molded plastic components.

Key Engineering Challenges & Solutions

| Challenge | NOVO’s Solution |

|---|---|

| Tightly integrated electromechanical design in a small form factor | Conducted comprehensive DFM review to identify simplification and integration opportunities |

| High cosmetic requirements for consumer-facing device | Aligned industrial design constraints with material and process guidelines to reduce surface defects |

| Complexity of mechanical fasteners and assembly steps | Implemented snap-fit designs and eliminated fasteners where possible |

| Assembly challenges due to part variation and complexity | Reduced fastener variety to improve assembly consistency and lower BOM complexity |

| Variants for different prescription types | Replaced multiple color-specific cap variants with a standardized cap, allowing color differentiation to occur at the point of use |

| Manufacturing interface for programming electronics | Designed hidden access point under product label to preserve cosmetic integrity |

Technical Innovations & System Design

Mechanical & Electrical Design

The smart cap and its paired reminder light were compact yet densely packed with components. NOVO analyzed the mechanical and PCB layouts to reduce part count and streamline assembly. Specific changes included:

- Snap-fit housing: Removed the need for screws and standoffs, improving manufacturability and reducing labor.

- Integrated LED features: Molded light guides directly into the front cover, eliminating several discrete parts.

- Cap stability enhancements: Modified the attachment interface to improve physical fit and reduce false readings.

Process Engineering

NOVO optimized component designs based on resin manufacturer guidelines to reduce visible defects such as sink and drag marks. These refinements were critical for a consumer-facing medical device with stringent aesthetic requirements.

Human Factors & Usability

Color coding was streamlined by transitioning from multiple molded cap variants to a single standardized cap, with differentiation handled at the point of use. This approach improved flexibility while simplifying production and inventory management.

Results & Impact

NOVO delivered a full documentation package, including updated 3D CAD and 2D drawings, on time and within budget. The improved design reduced assembly complexity, enhanced visual appeal, and made the product viable for high-volume production.

This work laid the foundation for what are now standard practices in connected therapeutics: user-centric design, remote monitoring, and integrated smart components. The device was ahead of its time, and NOVO helped make it manufacturable.

Why NOVO Engineering?

Years before the connected health trend became mainstream, NOVO was helping clients bring forward-looking solutions to life. Our expertise in DFM, system integration, and miniaturized electronics supports the development of visionary devices and bridges the gap between concept and large-scale production.

Whether you are launching the next smart health platform or refining an existing device, NOVO ensures your innovation is ready for the real world.

Let’s Talk

Have a connected health or IoT medical device challenge? Contact NOVO today to explore how we can help you bring your vision to market.