Developing a programmable, large-volume injector optimized for biologics and aseptic manufacturing

Client Need & Project Overview

On-body injectors—also known as wearable injectors—are subcutaneous drug delivery devices worn directly on the skin. They’re designed to administer medications in a patient-friendly format, often after a procedure or in place of inconvenient hospital visits. For biologics and other drugs that require large volumes or slow infusion rates, these devices help improve adherence, reduce pain, and control healthcare costs.

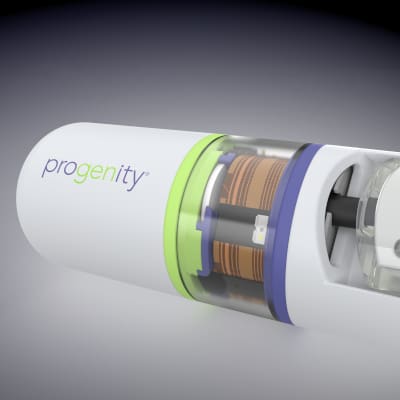

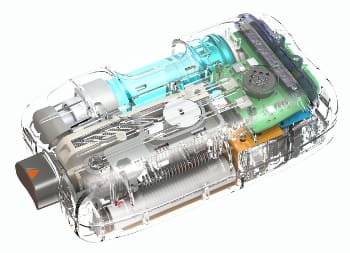

Unilife Corporation partnered with NOVO Engineering to develop a modular on-body injector platform capable of delivering viscous biologics in both 3 mL and 5 mL formats. The devices, later marketed as Flex Therapy® and Precision Therapy® Wearable Injectors, needed to combine automated functionality, patient usability, and compatibility with aseptic fill and finish manufacturing lines. NOVO was also engaged to support development of Unilife’s Imperium® insulin patch pump.

Key Engineering Challenges & Solutions

| Challenge | NOVO’s Solution |

|---|---|

| Miniaturization and mechanical complexity | Developed a compact, electromechanical layout with automated cannula insertion/retraction and programmable dosing. |

| Power efficiency | Engineered energy-efficient actuation and sensing systems to minimize onboard energy storage requirements. |

| Verification of dose delivery and error detection | Incorporated occlusion sensing and feedback indicators to confirm successful dosing or detect failures. |

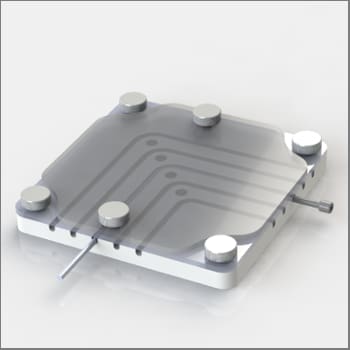

| Compatibility with aseptic manufacturing | Designed the fluid path to support automated aseptic fill and finish lines while maintaining a closed system. |

| Robustness and usability | Selected materials and designed housing to meet ingress protection, shock resistance, and ergonomic handling. |

Technical Innovations & System Design

Mechanical & Electrical Design:

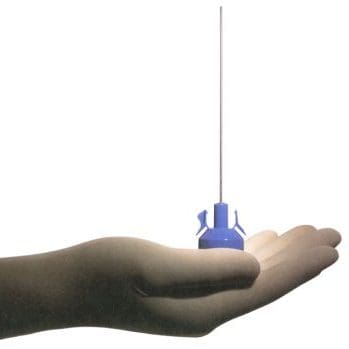

A firmware-controlled motorized mechanism enabled a pre-set dose schedule configured during manufacturing—a feature that aligns with how modern platforms are evolving to support variable or patient-specific dosing profiles. An automated soft cannula system simplified application and minimized steps required by the user.

Process Engineering:

The system was designed for compatibility with automated aseptic fill and finish lines—an approach increasingly important for modern high-throughput biologic production.

Sensing & Control:

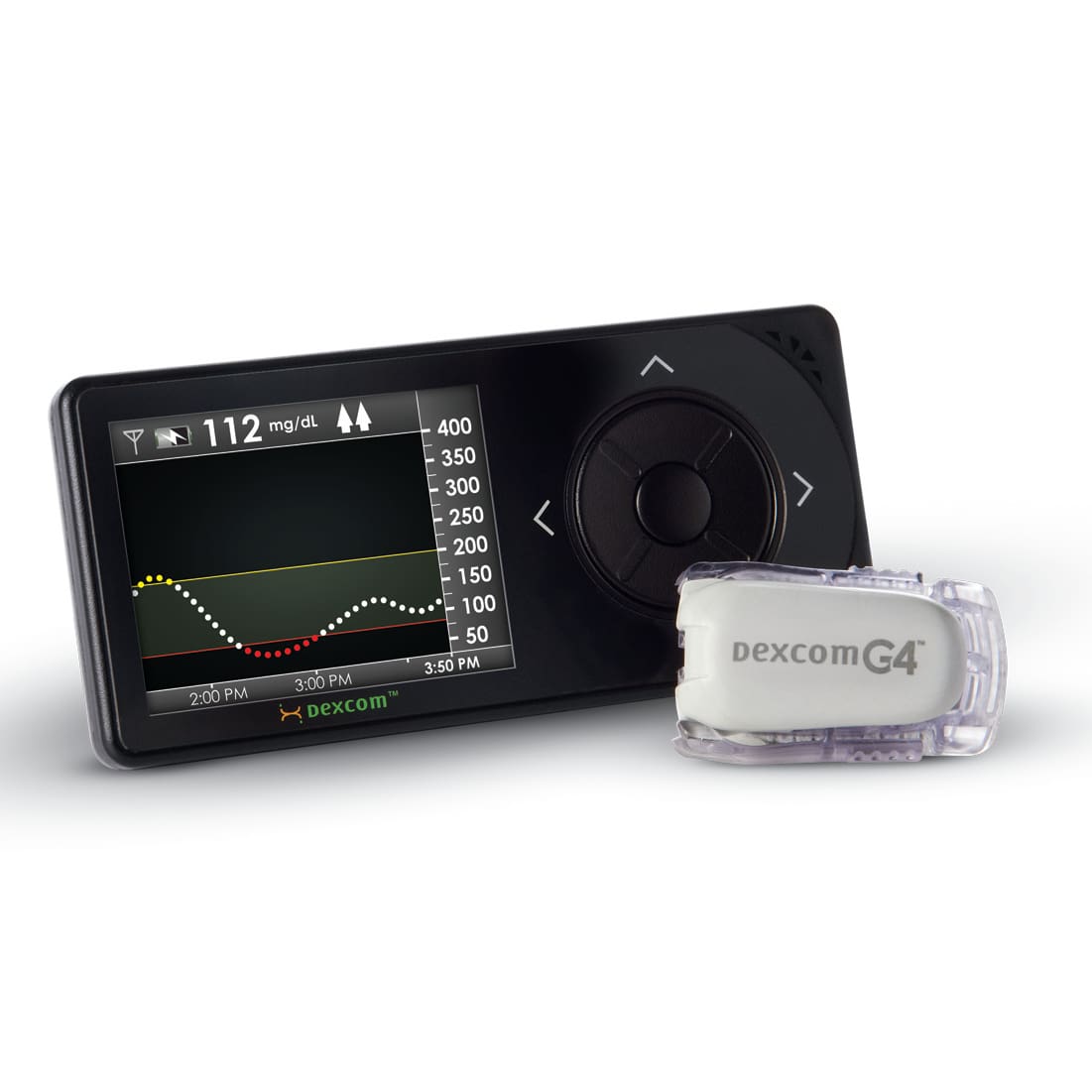

The platform included occlusion detection, dose confirmation, and error signaling—features increasingly seen in next-generation wearable devices. Firmware-driven logic enabled intelligent actuation and provided confidence in delivery without burdening the patient with additional steps.

Results & Impact

The foundational design elements developed during this program—closed-system drug paths, automated delivery, and programmable firmware—closely parallel the core features of many next-generation wearable injectors now on the market.

Why NOVO Engineering?

Many of today’s commercial wearable injectors share features NOVO implemented years earlier: closed fluid paths, automated insertion, programmable delivery, and error detection. By combining smart mechanical design with firmware control and process compatibility, NOVO delivered a solution that still aligns with modern medtech requirements. Our cross-disciplinary engineering ensures every aspect—from the patient interface to the manufacturing floor—is accounted for.

Let’s Talk About Your Project

Whether you’re a pharmaceutical company seeking a custom delivery platform or a device firm in need of engineering expertise, NOVO Engineering is ready to help. We support every stage of the development process, from concept to commercialization.

Contact us today to explore your next project.