Device Overview

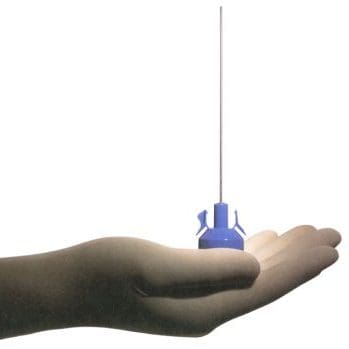

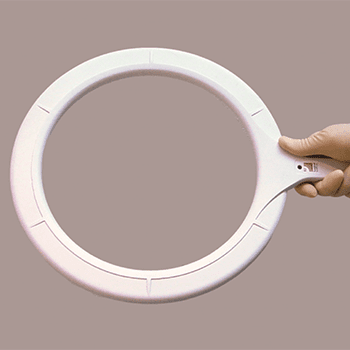

A startup client approached NOVO to develop a catheter delivery system for an resorbable vascular filter. The general approach is similar to a balloon catheter stent placement procedure. The vein is catheterized through the femoral or radial artery, the balloon and filter are fed over a guide wire to the desired location under fluoroscopic imaging, the balloon is inflated to set the filter, the balloon is deflated, and the catheter system is removed, leaving only the filter behind.

Filters, such as inferior vena cava (IVC) filters, are used to prevent pulmonary embolism caused by deep vein thrombosis (DVT), or blood clots formed in the legs. Traditionally, filters are of metallic construction. The recommendation is that filters be surgically removed once the risk of pulmonary embolism is determined to be tolerable; however, data shows that they are removed only in one third of cases, exposing patients to the risk of filter strut breakage and filter migration into the lungs.

Resorbable polymer filters avoid the need for a second surgical procedure to remove the filter. The risks of strut breakage and resulting damage to the vessel are theoretically eliminated.

Technical Challenges Designing the Catheter Delivery System

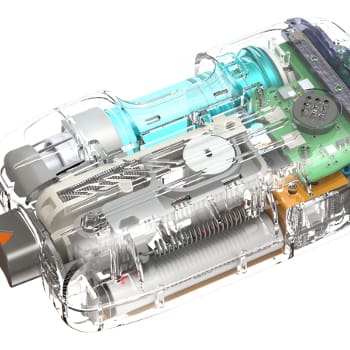

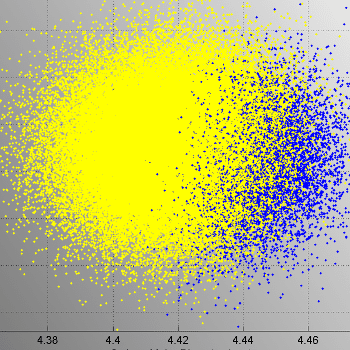

The primary technical challenges included miniaturization (16Fr introducer), retention and positioning of the filter during placement, filter retention after placement, verification of apposition, and filter deliverability.

Miniaturization of mechanisms naturally introduces technical risk. Manufacturing methods and tolerances that are perfectly acceptable for mechanisms at a macro scale may be inadequate for the same mechanism when miniaturized. Furthermore, as material cross-sections are reduced, creating a design with the required strength and flexibility becomes challenging.

During placement, the blood flow through the vessel creates hydrodynamic forces on the filter, so the filter must be mechanically retained. Once apposition against the vessel wall is confirmed, the retention mechanism must be remotely (at the handpiece) operated to release the filter. The retention mechanism must be extremely reliable, as a premature release of the filter might allow it to flow into the lung and cause an embolism.

Prior to intentional release of the filter, a means to verify that the filter is adequately apposed against the vessel wall must be provided. Otherwise, the same risks associated with premature release exist.

Delivering a System-level Solution

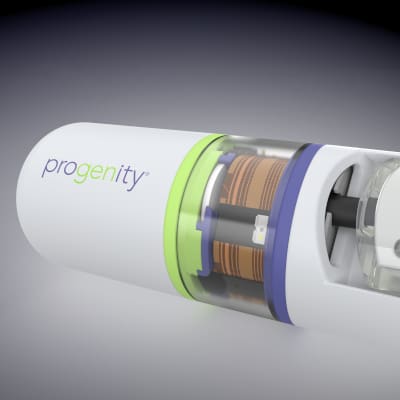

NOVO’s development team created a catheter and handpiece system that addressed the technical challenges as well as basic usability and performance criteria. Functional prototypes were delivered for preclinical testing.

The catheter required seven concentric layers to achieve all the required functionality, not including the introducer. These layers included the guide wire, multi-lumen tubing, sheath, balloon, filter, and two mechanism layers. All layers had to fit within the 16Fr introducer. Specialized fabrication and assembly methods were required.

A robust, miniature mechanism for retention of the filter during positioning and balloon inflation was developed. Operation of the release mechanism was achieved with a simple motion of surgeon’s thumb.

Balloon inflation with gauge and integrated overpressure protection was incorporated into the handpiece. Mechanical interlocks prevented out-of-sequence operations.

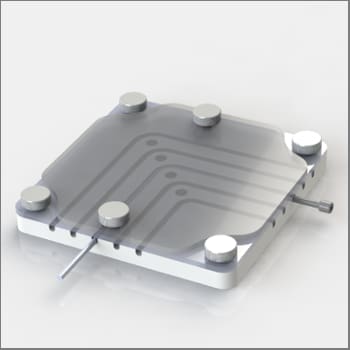

Several proprietary methods were developed to increase the flexibility of the intermediate layers of the catheter. The overall flexibility allowed the catheter to follow the guide wire through the relatively small bend radii in the femoral artery with minimal force. A fixture was developed for measuring pushabilty and trackability, which together comprise a measure of filter deliverabilty.

Radiopaque markers were designed to provide filter position data and to verify apposition between the filter and the vessel wall prior to balloon deflation.

Good Laboratory Practices

To support testing for good laboratory practices, NOVO performed two pilot manufacturing runs of the deployment system. These runs included packaging the devices. NOVO had also collaborated with the packaging vendor on custom packaging designs. The client then sent the packaged prototypes for sterilization via ethylene oxide and conducted preliminary tests on the devices, which performed well.

The final catheter delivery system designed by NOVO was an all-mechanical, single-use, handheld device comprising an introducer sheath, sheath retraction handle, safety interlocks, step-by-step user feedback indicators, and fill and flush ports for the saline solution that would inflate a balloon for expansion of the filter.