THE CLIENT’S NEED

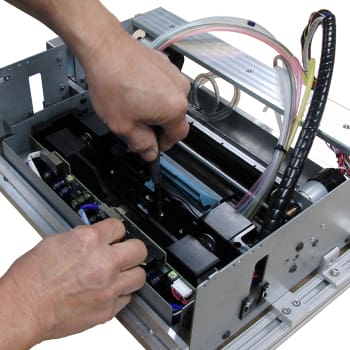

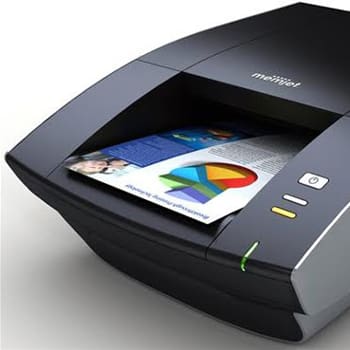

The client, a major printer manufacturer, had initiated an ambitious project to design a unified platform on which to base a variety of graphic and office printers. The printers were to be designed in the US and European offices and manufactured in high-volume plants in Asia. The client approached NOVO to provide lead engineering services to help architect the platform and then to participate in the printer design to ensure that the different design groups remained well coordinated.

THE TECHNICAL AND DESIGN CHALLENGES

This program presented both organizational and technical challenges. The platform architecture had to accommodate a variety of disparate printer designs without excessively penalizing any one design. For example, the graphic printer needed to print on much thicker media, which suggested a flat paper path and adjustable printhead-to-media gap, while the office printer had no such need. On the other hand, the office printer needed to have a much larger paper tray and greater print speeds than the graphic printer. The task was further complicated by the geographic and cultural differences between the teams designing the graphics and the office printer, and the fact that in NOVO’s position as architect, it was often necessary to give direction to members of the client’s staff or other sub-contractors.

THE ENGINEERING BEHIND GREAT PRODUCTS

NOVO’s team, consisting of a lead engineer and two senior engineers, worked full time on-site at the client’s facility for nearly a year to solve these problems. Tradeoffs were carefully analyzed, documented, and presented to all participants, leading to data-driven decisions and selection of an architecture acceptable to all participants. After the architecture process was complete, NOVO’s team helped drive many key innovations in the design, including footprint reduction, mechanisms for printhead height adjustment, and tools for media advance accuracy measurement. The designs were completed and transitioned to the contract manufacturer in Asia, where NOVO’s team worked directly with the contract manufacturer until the production process was stable.