CREATING A DNA PRINTER FOR PROTEIN OR ANTIBODY PRODUCTION:

Synthetic Genomics (SGI) engaged NOVO to develop a benchtop synthetic biology workstation, or “DNA printer.” The original model, the BioXp 3200, used the Gibson Assembly Method to assemble synthesized oligonucleotides (DNA fragments, a.k.a “oligos”) into longer chain molecules. SGI spun off a new company, Telesis Bio Inc., to focus on synthesis of DNA and mRNA for vaccines, immunotherapy, and other biological applications. The current instrument model is the BioXP 3250.

BioXP functions include automated assembly, error correction, amplification, and cloning of SGI’s synthesized DNA fragments. It automatically performs operations such as pipetting, mixing, thermal cycling, purification, and storage, which previously required multiple machines and manual intervention. The new DNA assembly platform was a natural complement to SGI’s line of high-value genomic reagents.

SGI initially had no in-house engineering resources and relied entirely on NOVO while internal staff was hired. NOVO helped SGI achieve their goal of developing a core in-house team without delaying project kickoff and execution. NOVO began the project with global responsibility, and as the in-house staff came up to speed, responsibilities were smoothly transitioned over. The split of responsibilities was as follows:

ENGINEERING RESPONSIBILITIES

NOVO

- Architecture design

- Concept and feasibility

- Deck platform design

- Lift rotation lid mechanism for thermal cycler

- Thermal cycler

- Thermal chillers

- All electronics, including PCA designs

- Thermal cycler control

- Chiller control—dual controls

- xy stepper motor controls

- z stepper motor control

- System cabling

- Oligo plate gripper mechanism

- All firmware on the NOVO-designed PCAs for stepper drivers, homing, thermal cycling control, PID control of thermal cycler and chillers, CAN bus communications between boards and panel PC, safety interlocks

- Fabrication of all parts

- System integration and testing

CLIENT

- xy gantry

- Outer skins (enclosure)

- ID for the outer skins and UI display

- Selection of panel PC

- Software on the panel PC (app code)

- Bio-security oligo plate carrier

TECHNICAL CHALLENGES: HIGH-PERFORMANCE THERMAL CYCLER

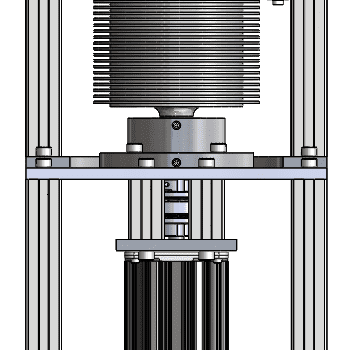

One of the key subsystems developed was a high-performance thermal cycler with ramp rates above 3.5°C/second from 3 – 100°C, accuracy of +/-0.1°C, and plate temperature uniformity of +/-0.6°C. These specifications were to be held across an entire 96-well plate. The design proved to be a complex systems engineering challenge. A combination of mechanical, control systems, electrical engineering, thermal analysis, and firmware design, as well as special machining and assembly techniques, were required. We worked closely with the thermoelectric cooler (TEC) supplier to optimize heat transfer rates and uniformity. A combination of theoretical analysis and empirical testing allowed the specifications to be met in only two hardware iterations. The custom thermal cycler also featured a unique, rotating lidding mechanism design driven by space considerations. The lidding mechanism was required to make tight seal to the well plate in order to prevent heat loss through evaporation.

Other technical challenges included full custom electronics, motion controls, rigidity and accuracy of the positioning system, custom labware, and integration complexity that arises when so many processes are combined in a benchtop instrument.

THE ENGINEERING BEHIND GREAT PRODUCTS

The finished product met the client’s performance requirements, and kept within budget and schedule constraints. It was successfully introduced into the market by SGI as the DNA Printer BioXp 3200 and won the 2015 North American Synthetic Biology New Product Innovation Award from Frost & Sullivan. US patent 9 446 407 was issued for the novel lidding mechanism.

NOVO collaborated with other partners during the course of the work: SGI and Nemko for regulatory testing and Laird Technologies for the thermoelectric modules.

The platform is still in use today in many labs where control over the entire workflow is critical. A higher-performance version, the BioXp 9600 is also available.