DEVELOPING A MULTI-CHANNEL MICROPLATE HEATER RACK

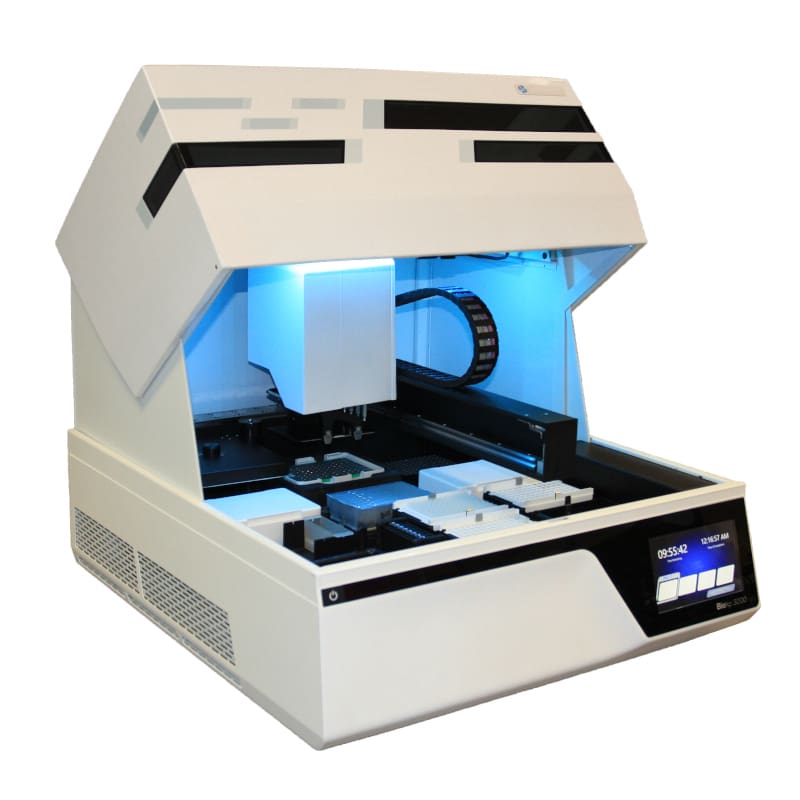

NOVO’s client, a fast-growing biotech company, had an existing microplate heater compatible with a high-throughput screening robot that utilized an RS232 interface for communication. The client challenged NOVO to design a more elegant plate heater and accompanying control box that would be cheaper and easier to assemble and maintain.

THE TECHNICAL AND DESIGN CHALLENGES

NOVO’s focus on this project centered on upgrading the control box architecture from discrete wiring to a custom-printed circuit board assembly and on improving system connections. The first-generation system relied heavily on discrete wiring for the integration of its individual components. This proved to be both highly labor-intensive and tedious to troubleshoot and maintain. NOVO engineers designed a custom printed circuit assembly (PCA) to replace the function of the discrete component system, eliminating most of the wiring in the process. This greatly reduced the labor and complexity involved in assembly as well as provided easier troubleshooting and maintenance.

THE ENGINEERING BEHIND GREAT PRODUCTS

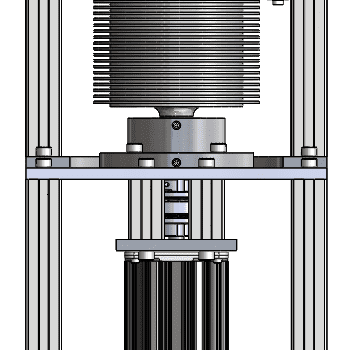

NOVO delivered two finished systems, each consisting of a control box integrated with a single-board computer that communicated with an array of digital programmable temperature controllers. Temperature controllers operated cartridge heaters embedded in both the upper or lower platens, allowing for independent thermal control of both the tops and bottoms of the plates.

Pneumatic actuators with end-of-stroke sensors provided operation of access doors and position feedback that could be used to prevent robot crashes. NOVO also manufactured all custom machined parts on this project.