Creating the World’s First DNA Printer

Client Need & Project Overview

The ability to synthesize DNA and mRNA on demand has become a cornerstone of modern synthetic biology, fueling rapid advances in vaccines, immunotherapies, and protein engineering. Long before today’s surge in automated DNA synthesis and lab-on-demand platforms, Synthetic Genomics (SGI) envisioned a benchtop synthetic biology workstation, essentially a DNA printer, that could assemble DNA fragments into longer molecules in a compact, automated format.

SGI selected NOVO as a design and engineering partner for the BioXp 3200, the world’s first commercial benchtop synthetic biology workstation. The system automated processes such as pipetting, mixing, thermal cycling, purification, and storage, steps that previously required multiple machines and significant manual intervention. The platform complemented SGI’s high-value genomic reagents and became the foundation for the BioXp product line. By integrating these reagents into a pre-programmed workflow, the BioXp platform unlocked a scalable, user-friendly way for scientists to move from raw materials to functional DNA and mRNA.

SGI later spun-out Telesis Bio Inc. to focus on this transformative technology. Today’s BioXp 3250 and BioXp 9600 workstations continue to power research across life sciences labs worldwide.

Key Engineering Challenges & Solutions

| Challenge | NOVO Solution |

|---|---|

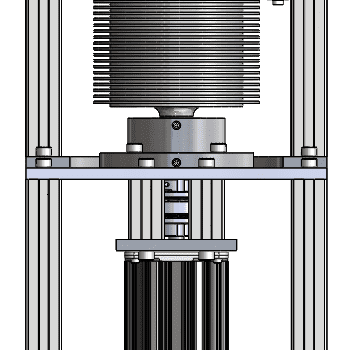

| Develop a thermal cycler with >3.5 °C/sec ramp rates, ±0.1 °C accuracy, and ±0.6 °C uniformity across a 96-well plate | Designed a high-performance custom thermal cycler using mechanical, electrical, and firmware engineering. Developed precision thermal control systems, dual chiller controls, and custom PCA boards for accuracy and repeatability. Optimized thermoelectric modules with the supplier and exceeded performance requirements in just two hardware iterations. |

| Prevent evaporation while minimizing instrument footprint | Created a novel rotating lidding mechanism to ensure thermal seal integrity. The design was later awarded U.S. Patent 9,446,407. |

| Integrate multiple laboratory processes into a compact benchtop format | Engineered custom electronics, precision motion controls, and rigid positioning systems. Developed custom labware and gripper mechanisms for seamless process integration. |

| Deliver manufacturability and regulatory compliance | Coordinated with Nemko for regulatory testing and Laird Technologies for thermal components. Ensured reliability and certifiability. |

Technical Innovations & System Design

Thermal Control and Precision Engineering

Achieved industry-leading temperature ramp rates and accuracy through advanced thermal design and analysis.

Compact Automation

Automated assembly, error correction, amplification, and cloning of SGI’s synthesized DNA fragments, consolidating what previously required multiple instruments and manual workflows into a single, seamless platform.

Custom Electronics and Motion Systems

Enabled precise liquid handling and mechanical control in a compact, reliable package.

Novel Mechanism Design

Introduced a patented rotating lid mechanism to improve seal integrity and thermal efficiency.

Engineering Scope

In addition to subsystem innovations, working in parallel with the client’s team, NOVO provided comprehensive engineering contributions that brought the BioXp platform to life.

NOVO Responsibilities

- Overall architecture design, concept development, and feasibility studies

- Deck platform design and integration of custom labware

- Complete electronics development, including PCA designs and system cabling

- Motion systems including x-, y-, and z-axis stepper motor controls and positioning systems

- Oligo plate gripper mechanism for accurate handling and placement

- Firmware development for NOVO-designed PCA boards, covering stepper drivers, homing routines, thermal cycling control, PID loops for cyclers and chillers, CAN bus communication, and safety interlocks

- Fabrication of custom parts and full system integration and testing to ensure a reliable, market-ready workstation

Client Responsibilities

- XY gantry design

- Outer skins (enclosure)

- Industrial design for the outer skins and UI display

- Selection of panel PC

- Application software on the panel PC

- Bio-security oligo plate carrier

Results & Impact

Commercial Launch

Released as the BioXp 3200, the first DNA printer and benchtop synthetic biology workstation of its kind.

Industry Recognition

Awarded 2015 North American Synthetic Biology New Product Innovation Award by Frost & Sullivan.

IP Protection

U.S. Patent 9,446,407 awarded for the innovative lidding mechanism.

Sustained Relevance

The platform remains in use globally, with successor models (BioXp 3250 and BioXp 9600) continuing to build on its engineering foundation.

Seamless System Integration

NOVO’s end-to-end engineering ensured that all subsystems, from firmware and motion control to thermal cycling and custom mechanics, were integrated and tested as a unified, reliable benchtop workstation.

Why NOVO Engineering?

Today, benchtop synthetic biology workstations and DNA printers are integral to life sciences research, enabling scientists to move faster from idea to discovery. These systems now support drug discovery, vaccine pipelines, and personalized medicine workflows that depend on automation and precision.

NOVO’s work on the BioXp platform showcased visionary engineering, proving that a compact, integrated DNA printer was not only possible but commercially viable. By tackling challenges in thermal control, firmware, motion systems, and multi-process integration, NOVO helped SGI establish the benchtop synthetic biology workstation category and accelerate the adoption of workflow automation in this space.

As the field continues to evolve toward higher throughput, digital integration, and cloud-connected lab systems, NOVO remains a trusted partner for innovators bringing the next generation of life sciences instruments to market.

Looking to develop a category-creating device like the benchtop synthetic biology workstation?

Contact NOVO today to explore how we can help turn your vision into reality.