Client Need & Project Overview

Syngenta, a global leader in agricultural science and plant genomics, needed a high-throughput automation solution to streamline sample preparation in its trait discovery pipeline. While NOVO had already helped develop a field-based sampling system that collected leaf tissue into custom cartridges, the next challenge was automating the transfer of those samples into standard 96-well microplates for laboratory analysis.

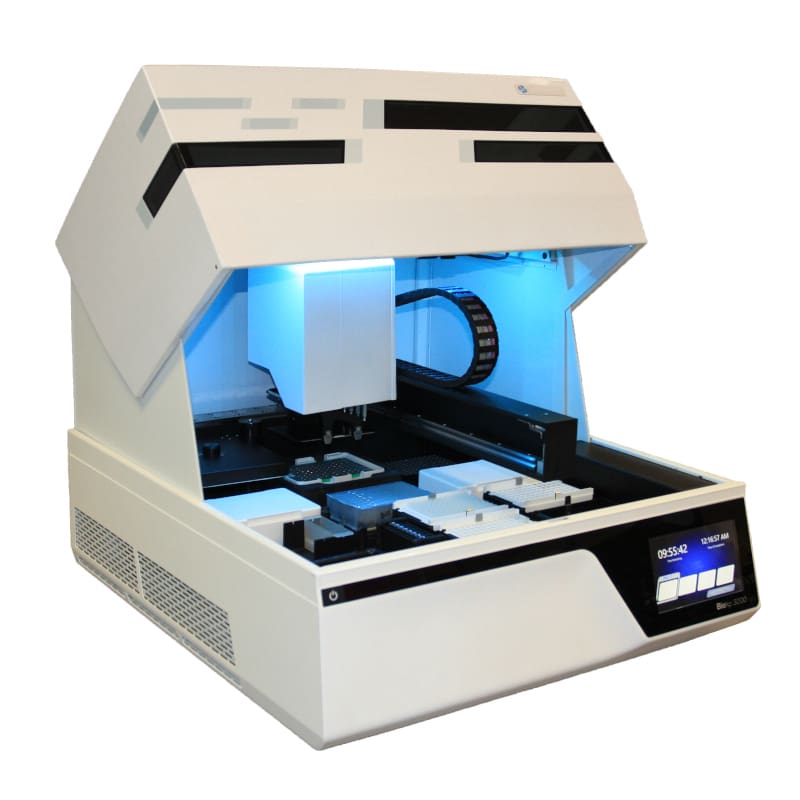

Syngenta partnered with NOVO to design a compact, robust reformatting robot that could handle hundreds of samples per run, preserve sample traceability, and fit seamlessly into the existing lab infrastructure.

Key Engineering Challenges & Solutions

| Challenge | NOVO’s Solution |

|---|---|

| High-volume, precise capsule positioning | Designed a cylindrical polar positioning system using cam-driven r-axis motion to reduce mechanical complexity and maintain precision |

| Increased throughput | Enabled automated transfer of ~800 capsules per run, achieving a throughput more than 8x higher than the prior single-station system |

| Space constraints | Engineered a compact, rigid system with optimized deck space to fit eight cartridges and 8 microplates on a standard lab bench |

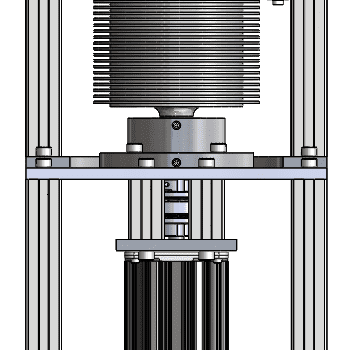

| Sticky biological material | Created a custom punch mechanism to reduce leaf tissue adherence during sample ejection |

| Data traceability | Developed software integration with Syngenta’s LIMS to track each sample from field to well |

Technical Innovations & System Design

Mechanical Design & Motion Architecture

To maximize efficiency while minimizing footprint, NOVO replaced conventional Cartesian motion systems with a cylindrical polar positioning system. This design used cam tracks embedded in a rotating platen to drive precise r-axis movement, simplifying the mechanics and eliminating the need for eight separate linear axes.

Custom hinging cartridge mounts allowed for quick loading and unloading, while keeping cartridges stable during operation. The result was a clean, compact machine optimized for high-speed performance in a lab environment.

Automation & Software Integration

Custom firmware synchronized all stages of the operation – aligning capsules over microplate wells, triggering plungers to eject tissue, and updating the LIMS with sample mapping data. This ensured traceability for downstream genetic analysis and enabled hands-off, repeatable processing.

Human Factors & Usability

Despite its throughput and technical sophistication, the system was designed for ease of use by lab personnel. The intuitive cartridge loading system and reliable automation helped reduce training time, minimize handling errors, and improve lab efficiency.

Results & Impact

- 8x increase in throughput – Completed reformatting runs significantly faster than prior systems

- Compact footprint – Designed to fit easily within standard bench layouts

- High sample integrity – Reduced material loss and minimized carryover risks

- Patented technology – Resulted in U.S. Patents 8 437 874 and 6 918 738

Why NOVO Engineering?

Long before lab automation became synonymous with modular robots and AI-enhanced workflows, NOVO was helping clients like Syngenta rethink scientific bottlenecks with custom automation solutions.

This collaboration exemplified NOVO’s ability to replace legacy lab processes with elegant, manufacturing-grade systems – designed from the ground up for precision, throughput, and seamless software integration.

Whether you’re advancing agriculture, life sciences, or diagnostics, NOVO delivers purpose-built engineering solutions that transform what’s possible in your lab.

Let’s build what’s next

If your team is facing a complex engineering challenge in life sciences, diagnostics, or medical devices, we’d love to help.

Contact NOVO today to explore how we can turn your concept into a reliable, manufacturable reality.