Reengineering a Realistic Simulation System for Mission-Ready Performance

Client Need & Project Overview

Simulation-based training has become essential for law enforcement and military readiness. Realistic, repeatable, and safe training platforms allow personnel to prepare for complex environments without the risks and restrictions of live fire exercises.

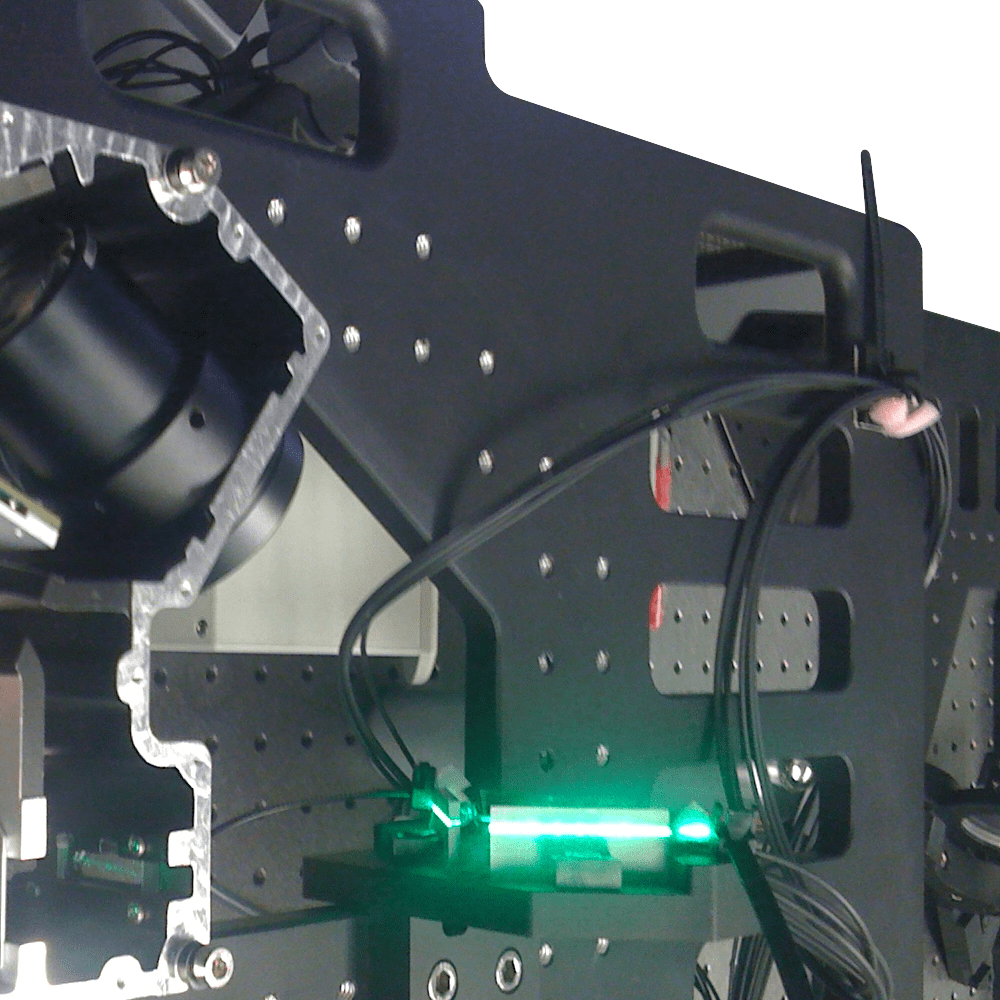

Unit Solutions engaged NOVO to recover a three-year effort to bring their UNIT4™ system, a non-lethal, high-fidelity training platform, to market. While NOVO typically focuses on medical, life sciences, and printing systems, the project’s safety-critical nature and engineering challenges made it a natural fit. The objective: transform a functional prototype with performance and documentation issues into a reliable, production-ready product.

Key Engineering Challenges & Solutions

| Challenge | NOVO’s Solution |

|---|---|

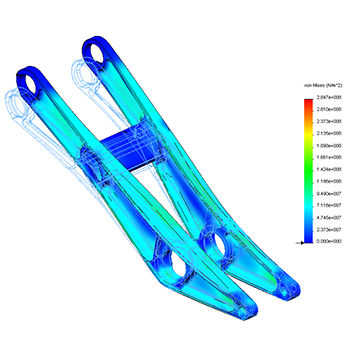

| Inconsistent trajectory and mechanical failures | Redesigned internal mechanisms for reliable CO2-propelled firing and accurate round trajectory |

| Rugged field use | Engineered for durability in dirt, moisture, and high-impact environments |

| Unstable automatic fire mode | Developed robust actuation for consistent auto and semi-auto operation |

| Missing documentation & supplier instability | Created complete production documentation and stabilized the supply chain |

| Non-production-ready design | Applied NOVO’s engineering process to justify each design decision with testing and analysis |

Technical Innovations & System Design

UNIT4™ mimics the handling of a real firearm—without the risk. Key technical features include:

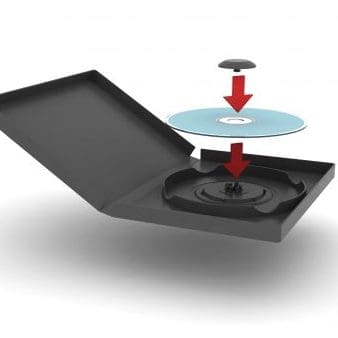

- Cassette-based marking rounds: Non-toxic, biodegradable rounds propelled by CO₂, offering tactile and visual hit confirmation.

- Realistic form factor: Magazine-fed, with the size, weight, and balance of a live firearm.

- Embedded safety: The platform cannot be modified to fire live ammunition.

- Scale-up support: NOVO developed cassette loading automation, plus jigs and fixtures for assembly, inspection, and testing. Every component was designed for consistent performance under harsh conditions.

Results & Impact

NOVO helped evolve the UNIT4 system from an unreliable prototype into a dependable, field-ready training tool.

- Proven field reliability: System validated under rigorous testing scenarios.

- Manufacturing-ready design: Complete documentation, streamlined assembly, and production fixtures enabled smooth transfer to manufacturing.

- Renewed market confidence: Product performance aligned with customer expectations in the military and law enforcement sectors.

Why NOVO Engineering?

Modern training platforms, rely on precision, safety, and user trust. NOVO’s experience with complex, high-stakes systems helped bring the UNIT4 platform to life.

At a time when the industry was beginning to recognize the potential of high-fidelity, non-lethal training tools, NOVO delivered a solution that aligned with the future of simulation-based readiness. By bringing discipline to design, production, and system reliability, we enabled Unit Solutions to fulfill its vision for safer, more effective training.

Let’s Talk

Facing performance or reliability issues in your system?

Contact NOVO to leverage our engineering and design expertise to successfully bring your solution to market.