DEVELOPING A 24/7/365 ALL-WEATHER, FLEXIBLE LED VIDEO DISPLAY

THE CLIENT’S NEED

A video display company had proprietary technology for outdoor LED video displays of individual pixels on open mesh. This concept allowed light to pass through the display, enabling mounting over windows, such as on a large office building, and it also allowed for mounting on curved surfaces of varying dimensions, unlike the solid, fixed-panel industry standards. After an initial contracting relationship ended, NOVO was brought in to perform complete product development, re-architecting the mechanics and electronics of the sign, the first of its kind.

THE TECHNICAL AND DESIGN CHALLENGES

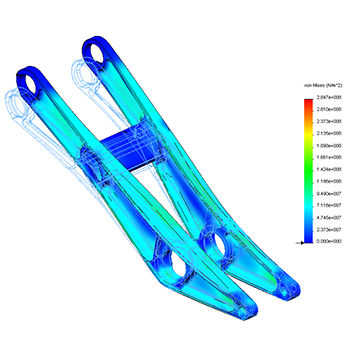

In addition to the open-mesh concept, which posed challenges in and of itself, NOVO engineers recognized that reliability and ingress protection were of paramount priority: if the display were mounted fifty stories up, access to the sign for repair and maintenance decreased. NOVO designed the sign to prevent damage from weather and failures of any type. Another challenge was ensuring the manufacturability of such a complex project.

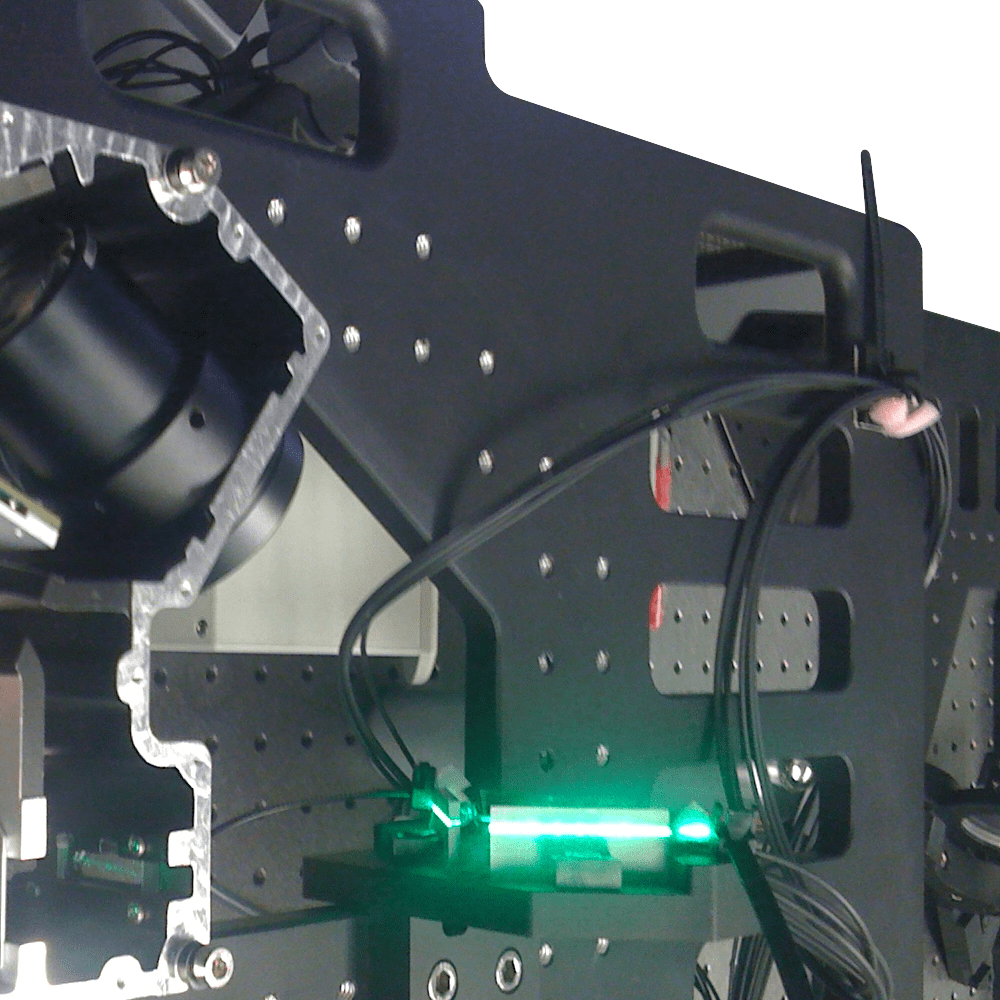

THE ENGINEERING BEHIND GREAT PRODUCTS

NOVO designed a fully modular, scalable architecture in which data distribution was redundant, permitting failures of up to three connections per module without disrupting data input. Each module had its own PC board and microprocessor. Power supply was also redundant, employing a system of masters and slaves to keep power failures from affecting more than logical strings of 16 modules. The NOVO team also developed low-voltage and line-voltage power supplies and enclosures along with proprietary connection systems for both power and data. The design still allowed for the entire display to have 50% open space and an IP6 rating.

Besides the system architecture, NOVO engineers developed manufacturing processes to encapsulate the electronics and to terminate the modules to the power and data backplanes. The manufacturing processes NOVO designed, along with automated equipment to execute them, helped resolve manufacturability issues and bring down cost while also facilitating serviceability.

It took NOVO 6 months to build the first prototype, and 6 months after that, the product was ready for first deployment. The sign handles 60 frame-per-second video, has a 7-bit color depth, and has been used in many high-profile settings, including as part of the New Year’s Eve “ball drop” in Times Square.

This project resulted in US patents 9 135 838, 8 922 458, 8 599 108, 8 558 755, and 8 648 774.