REDESIGNING A SUSPENSION LINK TO ELIMINATE FATIGUE FAILURES

Since the 1990s, full-suspension mountain bikes have gained popularity, with several styles of rear suspension now on the market. However, most rear suspension systems pose problems of energy loss during travel. A boutique mountain bike company had patents on technology based around a rocker-style suspension link that had lower potential energy loss than other models, but unfortunately, some of the rockers were failing. The bike company engaged NOVO to optimize the rocker by determining the cause of failure, implementing design changes to eliminate it, and applying those design changes while incorporating new cosmetic elements from an updated rocker on a different bike model. The final design had to be stronger, lighter, and more visually appealing than its predecessor.

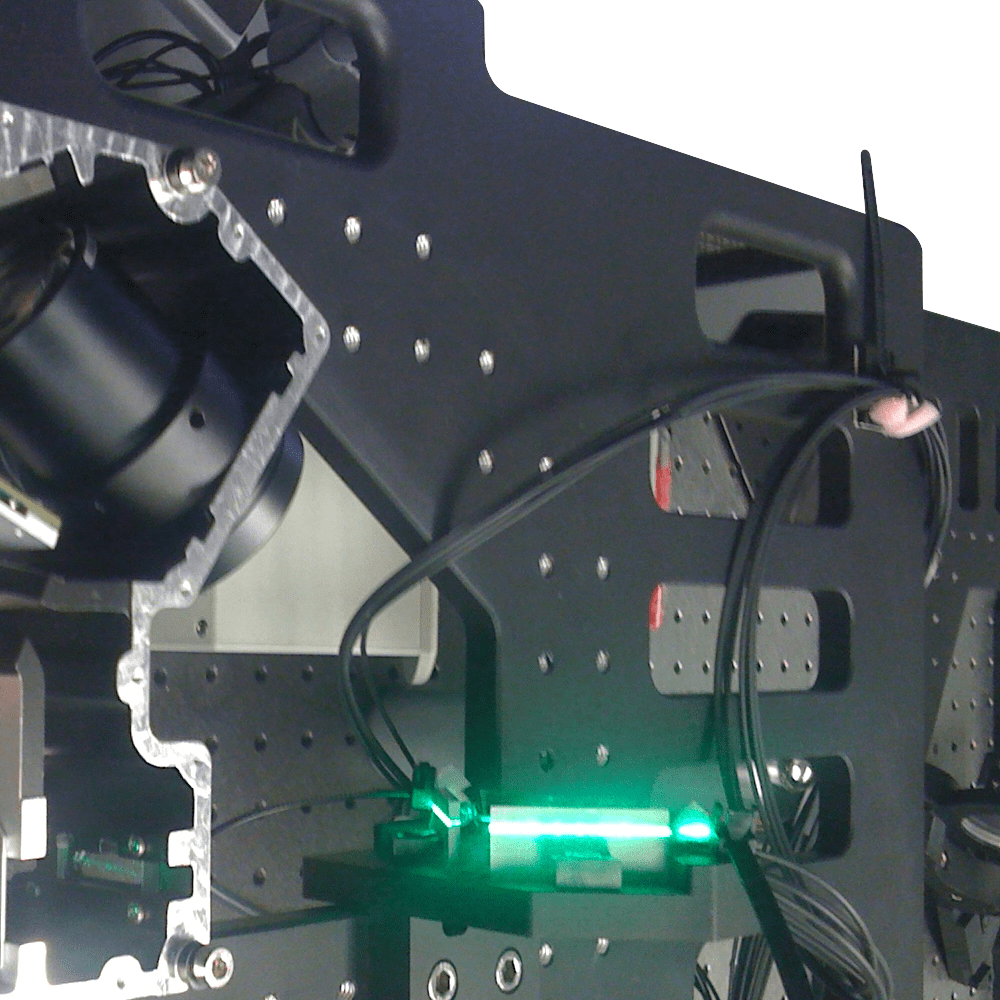

SUSPENSION LINK FINITE ELEMENT ANALYSIS

Finite element analysis (FEA) was used as a design tool to create a weight- and strength-optimized suspension link for a new mountain bike frame. External forces on the link under dynamic loading conditions were calculated and applied to the suspension link FEA. Fatigue failure calculations were compared to actual field failures to validate the model. With a suitable safety factor applied, the FEA model was used to enable rapid, intuitive design iterations of the cosmetically enhanced rocker, which quickly converged to a final design.

THE ENGINEERING BEHIND GREAT PRODUCTS

Besides applying the FEA, the engineers ensured the design was manufacturable and rugged. The stress distribution indicated where wall thicknesses could be reduced, which yielded at part weight below the client’s target without compromising durability. The client machined and fabricated NOVO’s design, assembled it onto a bike, and then sent it to a separate facility for life-cycle testing. The design passed all tests and has been in constant production since 2009.