About Matt

Matt is one of NOVO’s lead software engineers. Driven by fascination with all things hardware and software, he has initiated a long list of mechatronic and software side projects to broaden his skills and remain current. Below, Matt describes just a few of the many gadgets and gizmos he has created:

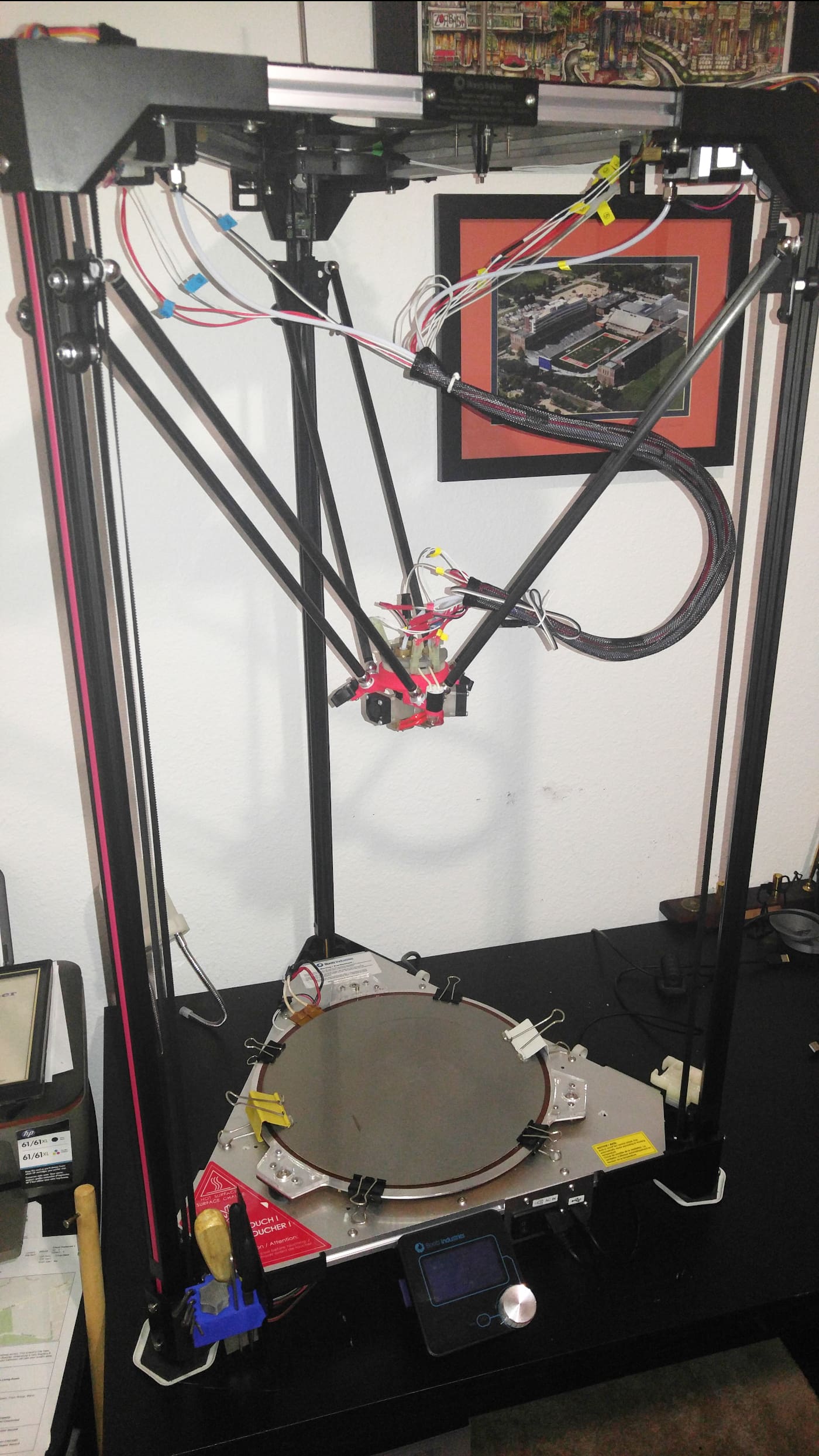

Delta 3D Printer

This is my 3D printer, Theseus. It’s a little different than the usual printer. The most noticeable difference is the “delta” design. Rather than your typical cartesian gantry, there’s 3 vertical towers with carriages that link to a central effector platform. The delta style lends itself to smoother curves in the x-y plane and enables larger vertical build volumes. What you see here is a cylindrical build volume of about 320mm diameter by 450mm height. I also have a Bowden style setup for the extruders, which reduces weight of the effector platform for faster movement.

It started as a kit I got from a Kickstarter about 7 years ago from a company that is now out of business. Some of the parts, like the frame, were really solid, but other parts not so much. For example, it originally came with fishing line instead of drive belts for the carriages. So I’ve made a bunch of upgrades on this machine over the years. I updated the vertical towers to use V-slot 2020 extrusion with wheel bearing carriages and actual drive belts. The linkage arms use magnet and ball-bearing connections for frictionless motion. The effector platform is custom-designed and 3D printed. It supports up to 3 hotends, but I’m currently only configured for 2 which I’ve upgraded to all-metal autolift ones. It’s hardly the same printer anymore, thus the name.

ePaper Display “Doggie Clock”

In the style of a “Days since last accident…” factory safety sign, DoggieClock tracks the time since our puppy’s last accident.

Or you can modify the code and track the passage of time for any event you desire.

My motivation for this project was mainly to experiment with tri-color ePaper displays (EPDs) and an ESP32. ePaper/eInk displays are perfect for this type of project because they only draw power when updating the screen, and paired with ESP32 low-power modes, the project should be able to run for a quite a bit on just a LiPo battery.

…And my other motivation was of course, Leroy himself…

Here is a link to the github repository with the build and code instructions:

https://github.com/Mrjohns42/DoggieClock