MODELING AND SIMULATION FOR DESIGN OPTIMIZATION

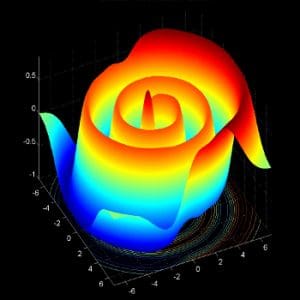

NOVO has modeling and simulation software for stress, fluid flow, dynamics, mathematical models, heat transfer, and electrical circuits. Finite element analysis tools allow a much broader range of geometry and material variations to be considered than would be practical with hardware prototyping alone. At NOVO, modeling and simulation techniques are used for comparative design optimization; when combined with actual test results to validate the model, simulation results can be used to predict performance.

NOVO’s in-house rapid prototyping and CNC machining allow us to use predictive design methods and “fast-failure” approaches in a complementary way. FEA tools, coupled with good old-fashioned engineering judgment can be significant accelerants to the product development process. And when conventional simulation tools are not suitable, NOVO’s systems engineering group has the analytical skills and software (e.g., Matlab, Simulink) to create a custom analysis for specialized engineering problems.

Modeling Tools And Capabilities

- FEA stress, thermal, CFD

- Kinematic analysis

- Statistical tolerance analysis

- MATLAB, Simulink

- Altium circuit simulation

- Custom analysis software