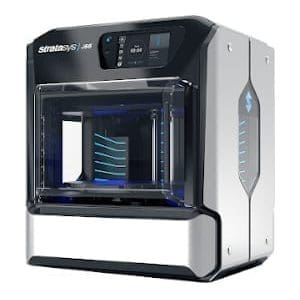

NOVO was a major development partner for the first company to commercialize a page-wide-array printer—a significant advancement in inkjet printing technology. The client company core competency was in CMOS/MEMS and they had developed an innovative low-cost thermal inkjet printhead suitable for use in multiple printer applications. Lacking expertise in printer design, testing, and commercialization, they chose NOVO as a long-term development partner and worked with NOVO for over five years. NOVO engineers worked closely with the client’s printhead team to develop printers for various market segments, including office, photo, label, and industrial printing.

Page-wide-array printheads offer the major simplification of eliminating the need for a moving carriage that sweeps across the width of the page; however, they introduce many new challenges that simply do not exist in conventional inkjet printing. Once such challenge, particularly on fine-pitch multi-color printheads, is color contamination.

COLOR CONTAMINATION

NOVO’s initial testing with the client’s printhead quickly uncovered excessive generation of aerosol mists and color contamination problems between closely spaced nozzles. NOVO’s team was able to study, understand, and resolve these problems through a combination of mechanical and fluidic changes in the print zone.

Our engineers developed custom imaging tools to visualize the problem and then analyze it based on an understanding of the physics of the observed phenomenon as well as on printing experience.

Some of the solutions included:

- Use of differential backpressures and adjustment of ink reservoir positions to selectively drive low-visibility inks toward high-visibility inks

- Use of surfactants in the inks to enhance beading on the printhead surface, thus making wiping easier

- Resetting of color profiles and use of optimized color orders

All the mechanical changes were then optimized for production and successfully transferred to manufacturing.

PRINTER INTELLECTUAL PROPERTY

The solutions for color contamination were just a few of the innovations made by NOVO’s team during the project. NOVO’s work on this project resulted in over 20 patents for the client and included other innovations such as paper shape and printhead-to-paper spacing control to meet a specification of 0.8 – 1.0mm, and paper feeding techniques to supply 60 sheets/minute to the printer.

These innovations enabled the development of home-and-office, label, and retail photo printers for the client.