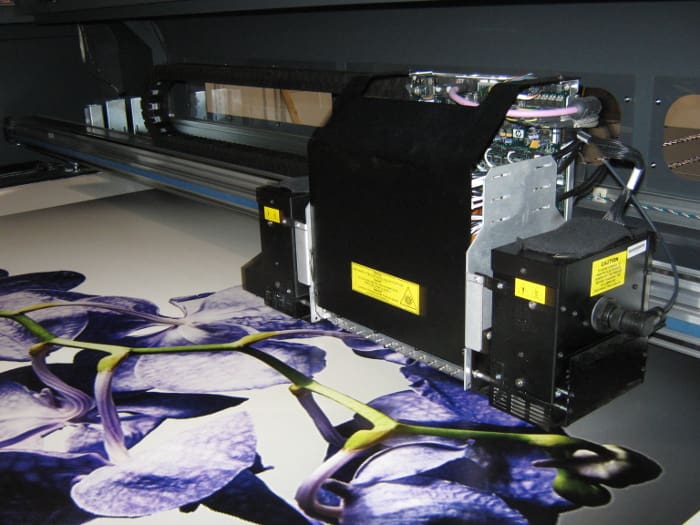

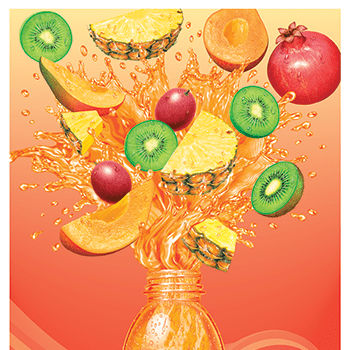

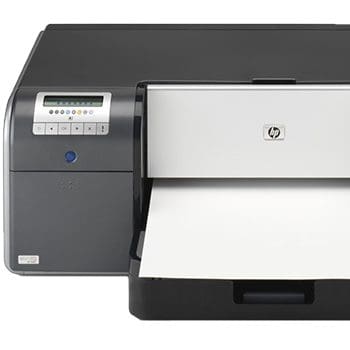

DEVELOPING A WIDE-FORMAT UV PRINTER FOR MULTIPLE SUBSTRATES AND APPLICATIONS

THE CLIENT’S NEED

NOVO engineers, while working at the client company, were asked to design a new type of cost-effective, grand-format UV printer using belt loading to allow continuous printing on rigid substrates in addition to printing to rolls on flexible substrates. Product development needed to include collapsible loading tables to save print shop floor space. The company assigned the project to one team of four mechanical engineers and two designers; a job of this scope normally requires several such teams.

THE TECHNICAL AND DESIGN CHALLENGES

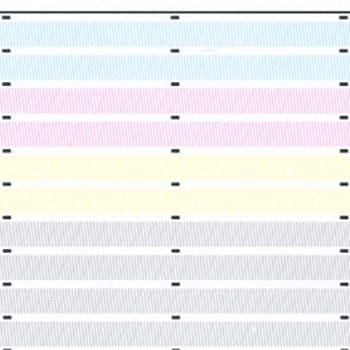

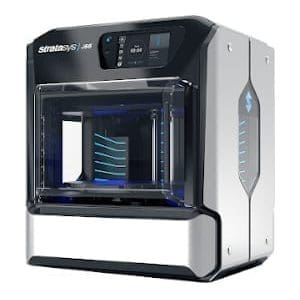

The biggest challenges of this project were media feed accuracy and ink delivery system (IDS) reliability. The media feed system was designed to provide accurate media movement at the 10-micron level for both rigid and flexible substrates. A detailed understanding of the drive roller system and vacuum hold-down system and the interactions between these systems was necessary to achieve the goal. The IDS reliability issue was addressed using a detailed failure mode analysis. Part count reduction, precision seal design, functional consolidation of filters and fittings, and improved control of the servicing and delivery functions played major roles in the overall improvement in reliability. Both the media movement and IDS improvements were subject to strict cost and schedule constraints.

THE ENGINEERING BEHIND GREAT PRODUCTS

Media advance accuracy challenges were resolved using a modified Pareto analysis approach. A detailed system accuracy model was created to identify the key contributors, and the cost associated with each of the contributors was considered to balance improvements in accuracy with increases in cost. Increased system rigidity and encoder accuracy were selected to double the media feed accuracy. Flexible media feeding issues, including media tracking problems and poor take-up quality, were eliminated with system drag refinement and an improved gear train design.

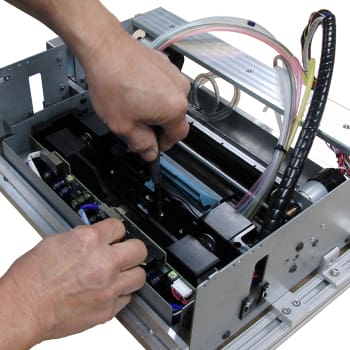

A number of solutions were implemented to address issues with the ink delivery system. The team removed components and reduced the number of fittings by an order of magnitude, resulting in fewer opportunities for failure. They also switched from complex to simple components while increasing the dimensional control of the remaining simpler components. Second, unique reservoir designs to eliminate ink frothing and its associated failure modes were successfully instituted, increasing the reliability of the ink delivery system even further. Additionally, the impact of printer operation and environment on ink temperature variation was minimized to add significant margin for ink pumping control.

The engineering team had extensive experience with new systems, which allowed them to consider time to market, value proposition, and innovation during design. Additionally, they leveraged expertise gleaned by working on internationally marketed products to anticipate and address safety, supply chain, and testing obstacles, ensuring reliability in the global market.

Both UV printers in this series have enjoyed higher-than-expected sales performance with continual growth since their release in 2010. In 2015, the team worked on a mid-life “kicker” project, implementing DFM/DFA changes, some cost reductions, and a greatly improved and enhanced version of the software. This work extended the market life of the product for a very small additional investment in development.

The entire design team from the client company transitioned to becoming NOVO employees when the client discontinued operations at the US location. NOVO was then awarded support and upgrade contracts by the client for four years, until the product reached end of life.